Ultimate Overview to Preventing Weld Undercut: Tips and Techniques

Ultimate Overview to Preventing Weld Undercut: Tips and Techniques

Blog Article

A Comprehensive Guide to Identifying, Averting, and Mending Undercut Welding Problems in Your Welding Projects

In the realm of welding, encountering undercut concerns is a common obstacle that can endanger the architectural integrity and overall quality of your welding tasks. Remain tuned as we discover the vital parts of determining, protecting against, and repairing undercut welding troubles, offering you with important insights and approaches to elevate your welding abilities to the following level.

Common Reasons For Undercut Welding

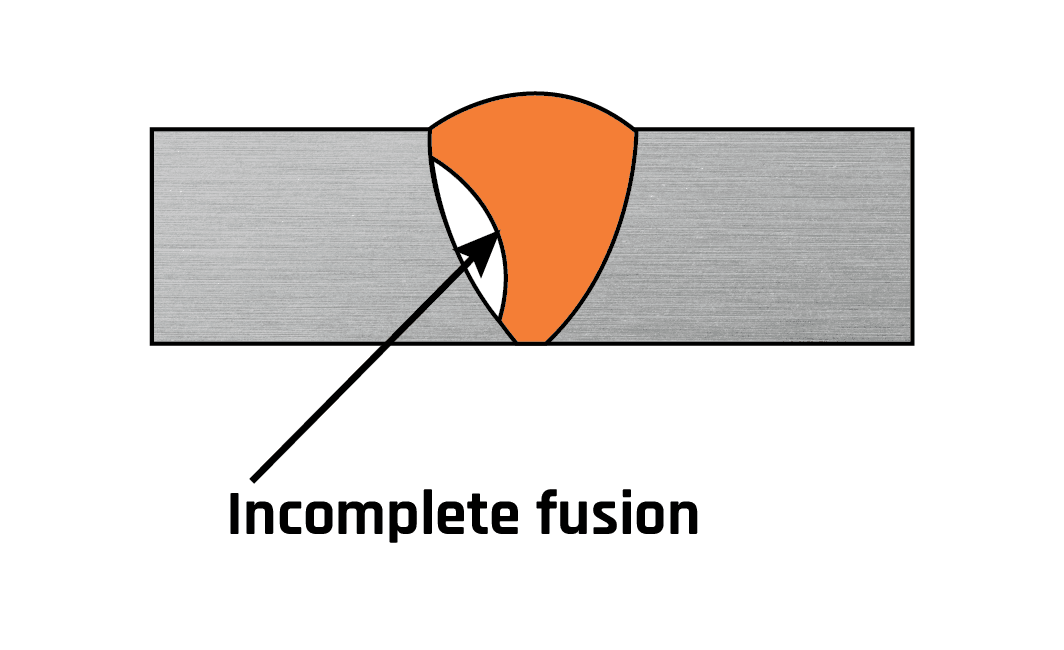

Undercut welding, a common problem in welding procedures, can be caused by numerous variables that need to be thoroughly recognized and dealt with to guarantee the stability of the weld joint. One of the main reasons for undercut welding is excessive heat input. When the welding criteria, such as voltage, present, or take a trip rate, are not effectively set, an excessive amount of warmth can be produced. This excess warmth leads to the melting and succeeding removal of the base material along the sides of the weld joint, producing a groove called undercut.

One more typical cause of undercut welding is inappropriate welding strategy. Insufficient manipulation of the welding torch or gun, incorrect angle or distance in between the lantern and the workpiece, or inconsistent travel rate can all add to the formation of undercut. Additionally, making use of the wrong welding consumables or electrode size for a particular joint setup can cause undercut issues. Determining these source and applying corrective procedures is vital in preventing and remedying undercut welding troubles in welding projects.

Identifying Undercut in Welds

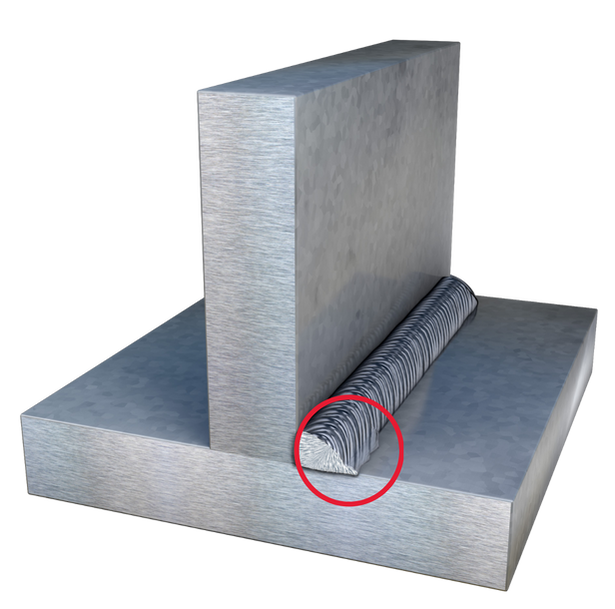

To determine undercut precisely, correct illumination and magnifying devices are vital to check the weld joint thoroughly. Utilizing tools such as a welding gauge or a magnifying glass can assist in spotting even the tiniest undercut imperfections. Additionally, running a finger or a fingernail along the weld joint can occasionally expose undercut, as the surface may really feel uneven or have a dip where the undercut exists.

Safety Nets for Undercut

Having a deep understanding of the root causes of undercut in welds allows for the application of effective safety nets to preserve weld top quality and honesty. One critical preventive step appertains weld joint prep work. Ensuring that the sides are clean, without contaminants, and appropriately beveled can substantially minimize the probability of undercut (Preventing weld undercut). Additionally, choosing the proper welding parameters, such as voltage, current, and travel rate, is crucial. These settings ought to be optimized to stop extreme warm input, which can lead to undercut development.

Strategies for Fixing Undercut

To deal with undercut issues properly, welders can utilize particular strategies aimed at correcting the problem and bring back the stability of the weld joint. One method is to change the welding specifications, such as the voltage, present, and travel rate, to browse around this web-site make certain correct warm input and fusion. Raising the welding present or decreasing the traveling speed can help complete the undercut. In addition, altering the welding strategy from a press to a drag or the other way around can additionally aid decrease undercut.

Another strategy is to utilize a weaving activity while welding to make certain correct sidewall fusion and fill in the undercut. By oscillating the welding arc back and forth within the weld joint, the welder can deposit extra filler material right into the undercut locations, effectively getting rid of the flaw.

In addition, grinding out the undercut and rewelding the joint can be a sensible solution for extra severe undercut issues - Preventing weld undercut. This procedure entails getting rid of the more information undercut area, preparing the base metal, and after that rewelding the joint with correct welding criteria and strategies to stop undercut from repeating

Professional Tips for Avoiding Undercut

Making use of correct welding strategies and keeping control over crucial welding parameters are essential techniques for welders aiming to avoid undercut in their weld joints. Additionally, choosing the appropriate welding process and filler steel for the specific application can help protect against undercut. Preserving a constant travel rate throughout the welding procedure is an additional important idea to avoid undercut.

Conclusion

To conclude, identifying, stopping, and taking care of undercut welding troubles in your welding jobs is critical for making certain resilient and strong welds. Preventing weld undercut. By understanding the typical reasons for undercut, having the ability to identify it in welds, executing safety nets, and utilizing proper techniques for dealing with undercut, you can avoid prospective issues and create top quality welds. Adhering to professional ideas for staying clear of undercut can aid you improve your welding skills and create better results in your projects

Undercut welding, an usual problem in welding procedures, can be created by various aspects that need to be carefully determined and addressed to make sure the stability of the weld joint. In addition, running a finger or a finger nail along the weld joint can occasionally reveal undercut, as the surface area might really feel uneven or have a dip where the undercut exists.

Utilizing correct welding strategies and keeping control over vital welding criteria are vital methods for welders intending to protect against undercut in their weld joints.In final thought, determining, avoiding, and repairing undercut welding issues in your welding projects is important for guaranteeing long lasting and solid welds. By comprehending the usual reasons of undercut, being able to identify it in welds, carrying out preventive actions, and making use of correct strategies for dealing he said with undercut, you can avoid possible concerns and develop top quality welds.

Report this page